The Story Of Amatoya - Yanko Design

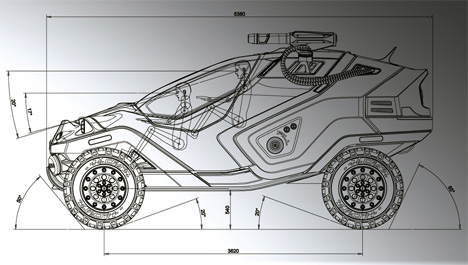

Amatoya is a concept reconnaissance and suppression vehicle that gives us a new approach to burn down-fighting. This highly avant-garde and specialized light tanker functions primarily as a reconnaissance vehicle and offers unmatched vehicle and crew safety/survivability. It promises to exist the all-time forepart line defence during the scene of an emergency. Read on to know more….

Details in Liam's words:

RECONNAISSANCE

Currently the role of site reconnaissance is predominantly carried out by light tankers or QAVs (Quick Attack Vehicles), typically these are modified single motel commercial utility vehicles such as the Toyota Landcruiser. While the off road functioning and maneuverability of such a vehicle is sufficient, its ability to actively suppress a fire threat is severely limited past the considerably modest water supply (500lt) and distinct lack of survival engineering, fundamentally making information technology inadequate for its role.

CREW LAYOUT

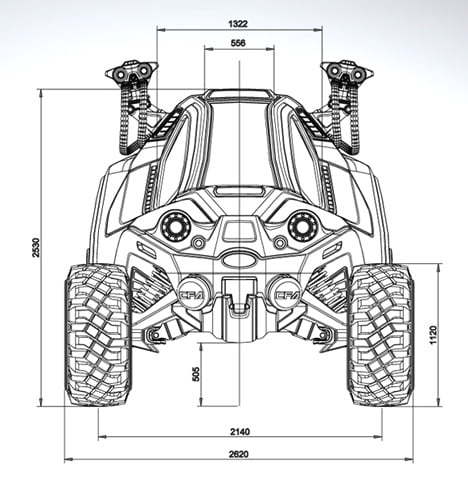

Typically medium and heavy tankers require 5-6 crew members to be operated effectively. AMATOYA requires only ii. More military in its approach, reducing crew numbers per appliance will permit for greater dispersion of resource during a burn down response.

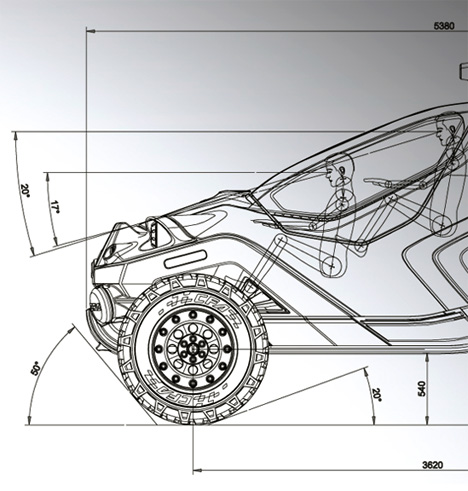

Main concerns when developing a vehicle of any nature are commuter position, ingress/egress and vision angles. These elements become even more crucial in a vehicle purpose built for reconnaissance. A central, forwards and high commuter and ROSCO operator position alike to the Apache set on helicopter with generous down vision will assure functionality.

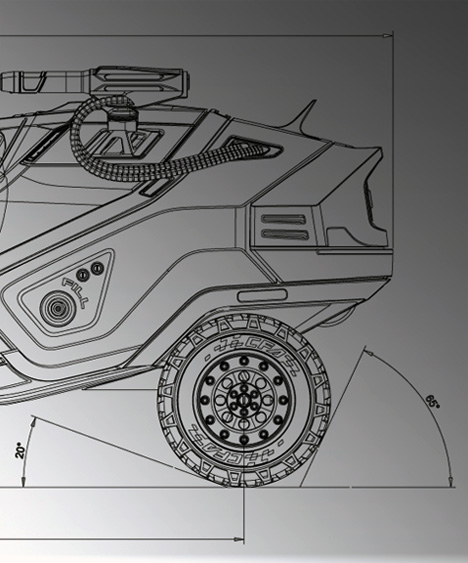

Access is via two dupe wing doors, an optimal solution to adapt the unconventional bodyside form. The distinct lack of a traditional b-colonnade will provide uninterrupted views for the ROSCO operator situated above and behind the driver.

SURVIVABILITY

Cabin temperature and vehicle survivability are central to the AMATOYA concept. Existing approaches in survival engineering on fire tankers consistently appears as augmentation rather than integration. Methods are passive, typically reactive and often incapacitate the appliance when in utilise. A central example is the use of drape rut shields, while effective, when employed render the apparatus out of operation.

To create a homogenous directive towards survivability AMATOYA incorporates state of the art clear aerogel laminated insulation in the windows and bodywork, a dedicated auxiliary water supply to operate a highly efficient, intelligent temperature controlled spray down organisation, military machine grade sacrificial thermo ceramic intumescent paints, and a mechanically injected large displacement diesel engine specifically engineered for the unique conditions experienced on the fire ground.

These measures will clinch that fifty-fifty in the case of an extremely prolonged and high intensity burnover the vehicle will non merely maintain cabin integrity, just opposed to existing appliances AMATOYA volition remain fully operational.

SUPPRESSION ABILITY

A Remotely Operated Suppression Cannon Outfit (ROSCO) coupled with a generous 1800lt + 400lt auxiliary water supply, offers a unique dynamic to vehicle operation. Current suppression techniques require large crew numbers (at least 5 per appliance) to perform through intermittent periods of strenuous labour to have any form of bear on on a burn. The ROSCO system utilizing IFEX3000 impulse technology is non only a hugely efficient means of fire suppression, but vitally will eliminate crew members existence subjected to the elements and stresses of extended loftier intensity piece of work on the fire ground, while constantly maintaining vehicle mobility. A highly rated thermal imaging photographic camera along with directional spot lights will assist in 'hotspot' location to determine the near effective direction of attack.

OFF Road PERFORMANCE

AMATOYA represents the acme of specialized performance in the burn down appliance design field. Off route capabilities reflect enthusiast 4WD methods, including generous approach, difference and over ramp angles, suspension travel, ground clearance and minimized plough circumvolve.

Key tire aggrandizement (CTI) and run flat tire (RFT) engineering coupled with beadlock tires will allow an extensive ring of dynamic pressure control to aid in traversing the complex terrain often encountered on the fire ground.

MANUFACTURING

The vehicle adopts many conventional fabrication techniques associated with low production run specialized vehicles. The point of deviation which separates this concept from existing appliances is the proposed monocoque steel trunk, comparable to armed forces MRAP vehicles. A conventional burn tanker is built torso-on-frame from a standard cab chassis truck base. While this approach is successful, the lack of integration results in certain performance bug. Body roll due to the on lath water supply is an notable problem, however past creating a fully integrated solution, water reservoirs tin can be strategically located central and low in the vehicle to dramatically better the middle of gravity.

You lot can voe for this project @ The James Dyson Awards.

Designer: Liam Ferguson

Source: https://www.yankodesign.com/2009/11/26/the-story-of-amatoya/

0 Response to "The Story Of Amatoya - Yanko Design"

Enregistrer un commentaire